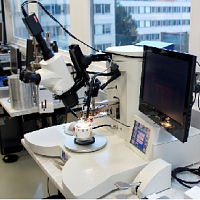

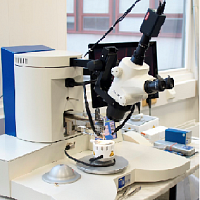

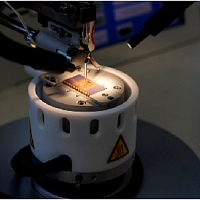

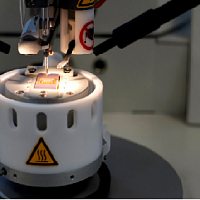

Wire bonder TPT HB 16

Wire bonding is a micro-welding technique for electrical interconnection of the sample substrate structures and semiconductor chip thin metallic layers. Contact between the sample surface and pure gold, alloyed aluminum or copper wire is provided by three main methods: ultrasonic, thermocompression and thermosonic bonding. The welding process is realized by wire attached to the substrate by bonding tool at the end of ultrasonic transducer, which is getting closer to certain distance to the sample surface. To achieve enhanced welding capability, sample is heated up to a certain temperature, for most processes being in the range from 20 °C to 250 °C. Attachment techniques defined by bonder tools are performed by wedge-wedge, ball-wedge, ribbon and bump bonding class.

Specification

Methods

- Ultrasonic, thermocompression and thermosonic capability - sample size up to 100 x 150 mm2 - ultrasonic transducer (62 kHz, up to 5 W power) - sample (chip) holder heated up to 250 °C, bonding tool heatable - gold or AlSi wires with diameters from 17 μm up to 75 μm and up to 25 μm x 250 μm ribbon compatible - adjustable wire loop between first and second bond with motorized holder movement - controlling software allows possibility to store up to 100 recipesPublications

Horký, M., 2025: Controlling the magnetic phase transition in spatially confined structures. PH.D. THESIS, p. 1 - 181 (RAITH, MIRA-EBL, LYRA, SUSS-MA8, DEKTAK, NANOCALC, MAGNETRON, EVAPORATOR, RIE-FLUORINE, WIRE-BONDER, MPS150, CRYOGENIC, LAKESHORE, VERSALAB, ICON-SPM, TITAN, HELIOS, VERIOS, RIGAKU3, RIGAKU9)

SUPALOVÁ, L.; BARTOŠÍK, M.; ŠVARC, V.; MACH, J.; PIASTEK, J.; ŠPAČEK, O.; KONEČNÝ, M.; ŠIKOLA, T., 2025: High-Temperature Ultrasensitive FET-Based CVD Graphene Hall Probes. ACS APPLIED ELECTRONIC MATERIALS 7 (13), p. 5889 - 5897, doi: 10.1021/acsaelm.5c00351 (DWL, SUSS-MA8, EVAPORATOR, MIRA-EBL, RIE-FLUORINE, WIRE-BONDER, WITEC-RAMAN, LYRA)

TAKHSHA GHAHFAROKHI, M.; HORKÝ, M.; NASI, L.; KOSOGOR, A.; TREVISI, G.; CASOLI, F.; ARREGI URIBEETXEBARRIA, J.; BRESCIA, R.; UHLÍŘ, V.; ALBERTINI, F., 2025: Spatially confined magnetic shape-memory Heuslers: Implications for nanoscale devices. ACTA MATERIALIA 284, p. 1 - 11, doi: 10.1016/j.actamat.2024.120579 (VERIOS, MIRA-EBL, RIE-FLUORINE, VERSALAB, WIRE-BONDER)

Koňařík, L., 2024: Development and fabrication of microelectromechanical systems MEMS. BACHELOR'S THESIS, p. 1 - 46 (LASER-DICER, DWL, EVAPORATOR, RIE-FLUORINE, DRIE, NANOCALC, DEKTAK, WIRE-BONDER, LYRA)

KOVAŘÍK, M.; CITTERBERG, D.; PAIVA DE ARAÚJO, E.; ŠIKOLA, T.; KOLÍBAL, M., 2024: Understanding the Effect of Electron Irradiation on WS2 Nanotube Devices to Improve Prototyping Routines. ACS APPLIED ELECTRONIC MATERIALS 6 (12), p. 8776 - 7, doi: 10.1021/acsaelm.4c01450 (ALD-FIJI, MIRA-EBL, EVAPORATOR, MPS150, KEITHLEY-4200, LYRA, WITEC-RAMAN, WIRE-BONDER, NANOSCAN)

JAKEŠOVÁ, M.; KUNOVSKÝ, O.; GABLECH, I.; KHODAGHOLY, D.; GELINAS, J.; GLOWACKI, E., 2024: Coupling of photovoltaics with neurostimulation electrodes-optical to electrolytic transduction. JOURNAL OF NEURAL ENGINEERING 21 (4), doi: 10.1088/1741-2552/ad593d (PARYLENE-SCS, MAGNETRON, SUSS-MA8, EVAPORATOR, RIE-FLUORINE, DIENER, WIRE-BONDER)

Otýpka, M., 2024: Electric-current Control of Magnetic Textures in Synthetic Antiferromagnets. BACHELOR'S THESIS, p. 1 - 56 (MAGNETRON, VERSALAB, DWL, WIRE-BONDER, KERR-MICROSCOPE)

Kunc, J.; Fridrišek, T.; Shestopalov, M.; Jo, J.; Park, K., 2024: Graphene–insulator–metal diodes: Enhanced dielectric strength of the Al2O3 barrier. AIP ADVANCES 14 (9), p. 1 - 9, doi: 10.1063/5.0223763 (RAITH, RIE-FLUORINE, ALD-FIJI, EVAPORATOR, WIRE-BONDER, KRATOS-XPS)

HRUBÝ, J.; LAGUTA, O.; SOJKA, A.; ST. MARIE, L.; MYERS-WARD, R.; GASKILL, K.; EL FATIMY, A.; BARBARA, P.; NEUGEBAUER, P., 2024: Graphene quantum dot bolometer for on-chip detection of organic radical. APPLIED PHYSICS LETTERS 124 (12), p. 1 - 6, doi: 10.1063/5.0191087 (WIRE-BONDER)

Hnilica, J., 2023: Current-induced domain wall propagation in ferrimagnetic wires. MASTER'S THESIS (MAGNETRON, VERSALAB, RIGAKU9, SUSS-RCD8, DWL, WIRE-BONDER, KERR-MICROSCOPE)

ŠVARC, V.; BARTOŠÍK, M.; KONEČNÝ, M.; PIASTEK, J.; NEZVAL, D.; MACH, J.; ŠIKOLA, T., 2023: Side charge propagation in simultaneous KPFM and transport measurement of humidity exposed graphene FET sensor. CARBON 215, p. 118471 - 12, doi: 10.1016/j.carbon.2023.118471 (RIE-FLUORINE, EVAPORATOR, MIRA-EBL, WIRE-BONDER)

GABLECH, I.; BRODSKÝ, J.; VYROUBAL, P.; PIASTEK, J.; BARTOŠÍK, M.; PEKÁREK, J., 2022: Mechanical strain and electric-field modulation of graphene transistors integrated on MEMS cantilevers. JOURNAL OF MATERIALS SCIENCE 57 (3), p. 1923 - 13, doi: 10.1007/s10853-021-06846-6 (RIE-FLUORINE, DRIE, EVAPORATOR, WIRE-BONDER, WITEC-RAMAN, MPS150, KEITHLEY-4200, SUSS-MA8, DWL)

Fridrišek, T., 2022: Optical gating of epitaxial graphene. MASTER'S THESIS (MIRA-EBL, RIE-FLUORINE, EVAPORATOR, LYRA, WIRE-BONDER)

Vaňatka, M., 2021: Static and dynamic properties of nanostructured magnetic materials. PH.D. THESIS, p. 1 - 113 (VERSALAB, VNA-MPI, TITAN, BRILLOUIN, MIRA-EBL, RAITH, KERR-MICROSCOPE, MAGNETRON, EVAPORATOR, VERIOS, WIRE-BONDER, LYRA)

GHAHFAROKHI, M.; ARREGI URIBEETXEBARRIA, J.; CASOLI, F.; HORKÝ, M.; CABASSI, R.; UHLÍŘ, V.; ALBERTINI, F., 2021: Microfabricated ferromagnetic-shape-memory Heuslers: The geometry and size effects. APPLIED MATERIALS TODAY 23, p. 101058-1 - 11, doi: 10.1016/j.apmt.2021.101058 (VERSALAB, RIGAKU9, KERR-MICROSCOPE, SUSS-MA8, RIE-FLUORINE, EVAPORATOR, WIRE-BONDER, VERIOS)

Dhankhar, M.;, 2021: Magnetic vortex based memory device. PH.D. THESIS, p. 1 - 100 (KERR-MICROSCOPE, ICON-SPM, DWL, MIRA-EBL, RAITH, KAUFMAN, EVAPORATOR, MAGNETRON, ALD-FIJI, WIRE-BONDER, SUSS-RCD8)

Tesař, J., 2020: Fabrication and characterization of atomically thin layers. MASTER'S THESIS, p. 1 - 67 (WITEC-RAMAN, MPS150, UHV-LEEM, EVAPORATOR, RAITH, ICON-SPM, WIRE-BONDER)

Chmela, O., 2020: Progress toward the development of single nanowire-based arrays for gas sensing applications. PH.D THESIS, p. 1 - 199 (ALD-FIJI, DWL, KAUFMAN, DIENER, SUSS-MA8, SUSS-RCD8, RAITH, MAGNETRON, EVAPORATOR, RIE-FLUORINE, SCIA, DEKTAK, ICON-SPM, NANOCALC, MPS150, WIRE-BONDER)

GABLECH, I.; KLEMPA, J.; PEKÁREK, J.; VYROUBAL, P.; HRABINA, J.; HOLÁ, M.; KUNZ, J.; BRODSKÝ, J.; NEUŽIL, P., 2020: Simple and efficient AlN-based piezoelectric energy harvesters. MICROMACHINES 11 (2), p. 1 - 10, doi: 10.3390/mi11020143 (DRIE, RIE-CHLORINE, WIRE-BONDER, KAUFMAN)

Hache, T.; Vanatka, M.; Flajsman, L.; Weinhold, T.; Hula, T.; Ciubotariu, O.; Albrecht, M.; Arkook, B.; Barsukov, I.; Fallarino, L.; Hellwig, O.; Fassbender, J.; Urbanek, M.; Schultheiss, H., 2020: Freestanding Positionable Microwave-Antenna Device for Magneto-Optical Spectroscopy Experiments. PHYSICAL REVIEW APPLIED 13 (5), p. 054009-1 - 10, doi: 10.1103/PhysRevApplied.13.054009 (RAITH, RIE-FLUORINE, EVAPORATOR, WIRE-BONDER, BRILLOUIN)

Citterberg, D., 2019: Integration of nanostuctures into functional devices. MASTER'S THESIS, p. 1 - 50 (MIRA-EBL, EVAPORATOR, WITEC-RAMAN, WIRE-BONDER, TITAN, MPS150)

Hegrová, V., 2019: Application of correlative AFM/SEM microscopy. MASTER'S THESIS, p. 1 - 64 (LYRA, MIRA-EBL, RIE-FLUORINE, EVAPORATOR, WIRE-BONDER)

CHMELA, O.; SADÍLEK, J.; SAMA, DOMENECH-GIL, G.; J.; SOMER, J.; MOHAN, R.; ROMANO-RODRIGUEZ, A.; HUBÁLEK, J.; VALLEJOS VARGAS, S., 2018: Selectively arranged single-wire based nanosensor array systems for gas monitoring. NANOSCALE 10 (19), p. 9087 - 10, doi: 10.1039/c8nr01588k (RAITH, DWL, KAUFMAN, MAGNETRON, SCIA, RIE-FLUORINE, WIRE-BONDER, RIGAKU3)

Křižáková, V., 2018: Spin wave excitation and propagation in magnonic crystals prepared by focused ion beam direct writing. MASTER'S THESIS, p. 1 - 83 (LYRA, HELIOS, KERR-MICROSCOPE, ICON-SPM, MIRA-EBL, EVAPORATOR, WIRE-BONDER)

SVATOŠ, V.; GABLECH, I.; PEKÁREK, J.; KLEMPA, J.; NEUŽIL, P., 2018: Precise determination of thermal parameters of a microbolometer. INFRARED PHYSICS & TECHNOLOGY 93, p. 286 - 5, doi: 10.1016/j.infrared.2018.07.037 (WIRE-BONDER)

Procházka, P., 2018: Fabrication of graphene and study of its physical properties. PH.D. THESIS, p. 1 - 139 (ALD-FIJI, DIENER, EVAPORATOR, MIRA-EBL, PECVD, WIRE-BONDER)

MACH, J.; PROCHÁZKA, P.; BARTOŠÍK, M.; NEZVAL, D.; PIASTEK, J.; HULVA, J.; ŠVARC, V.; KONEČNÝ, M.; KORMOŠ, L.; ŠIKOLA, T., 2017: Electronic transport properties of graphene doped by gallium. NANOTECHNOLOGY 28 (41), p. 1 - 10, doi: 10.1088/1361-6528/aa86a4 (DIENER, DWL, EVAPORATOR, WIRE-BONDER, LYRA)

HRDÝ, R.; KYNCLOVÁ, H.; KLEPÁČOVÁ, I.; BARTOŠÍK, M.; NEUŽIL, P., 2017: Portable Lock-in Amplifier-Based Electrochemical Method to Measure an Array of 64 Sensors for Point-of-Care Applications. ANALYTICAL CHEMISTRY 89 (17), p. 8731 - 7, doi: 10.1021/acs.analchem.7b00776 (MPS150, WIRE-BONDER)

PROCHÁZKA, P.; MAREČEK, D.; LIŠKOVÁ, Z.; ČECHAL, J.; ŠIKOLA, T., 2017: X-ray induced electrostatic graphene doping via defect charging in gate dielectric. SCIENTIFIC REPORTS 7, p. 1 - 7, doi: 10.1038/s41598-017-00673-z (MIRA-EBL, DIENER, ALD-FIJI, WIRE-BONDER)

VAŇATKA, M.; URBÁNEK, M.; JÍRA, R.; FLAJŠMAN, L.; DHANKHAR, M.; IM, M.; MICHALIČKA, J.; UHLÍŘ, V.; ŠIKOLA, T., 2017: Magnetic vortex nucleation modes in static magnetic fields. AIP ADVANCES 7 (10), p. 1 - 8, doi: 10.1063/1.5006235 (DWL, EVAPORATOR, RAITH, TITAN, WIRE-BONDER)

Turčan, I., 2017: Study of Magnonic Crystals in a Frequency Domain. MASTER'S THESIS, p. 1 - 55 (MIRA-EBL, EVAPORATOR, MAGNETRON, WIRE-BONDER)

Holobrádek, J., 2017: Transport Properties of One Magnetic Nanostructures. BACHELOR'S THESIS, p. 1 - 48 (CRYOGENIC, TITAN, ICON-SPM, MIRA-EBL, EVAPORATOR, WIRE-BONDER)

Citterberg, D., 2017: Preparation of contacts to one-dimensional nanostructurs. BACHELOR'S THESIS, p. 1 - 26 (DWL, MIRA-EBL, WIRE-BONDER, EVAPORATOR)

Vaňatka, M., 2017: Fabrication and characterization of nanostructures with functional properties in the field of spintronics. TREATISE TO STATE DOCTORAL EXAM, p. 1 - 31 (TITAN, MIRA-EBL, EVAPORATOR, MAGNETRON, WIRE-BONDER, LYRA)